Part Quality Control

Digitalize your quality control process to meet demanding requirements for product quality and dimensional accuracy. By integrating CMM inspection programming, shop floor execution, and measured data analysis, you can establish an efficient data-driven quality control process.

This automated, closed-loop solution enables continuous process control, so you can deliver high-quality products and stay competitive.

Powerful features for part quality control are

- CMM Inspection Programming

- Inspection Data Analysis

- Inspection Program Execution

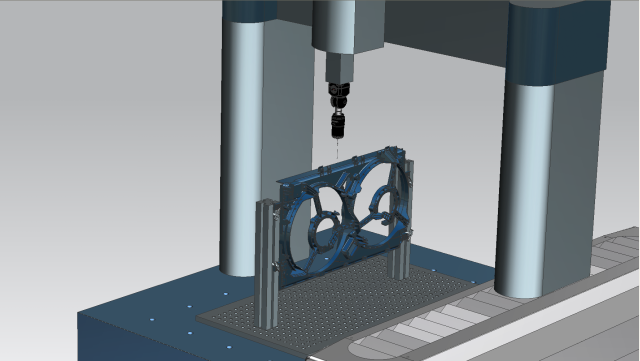

CMM Inspection Programming

- NX™ CMM Inspection Programming software provides a state-of-the-art solution for offline programming that reduces programming time, frees up expensive CMM machines, and ensures a fast response to design changes.

- By combining industry knowledge and best practices with process automation, our solution streamlines the entire inspection program development process from feature definition and path creation to program generation and validation.

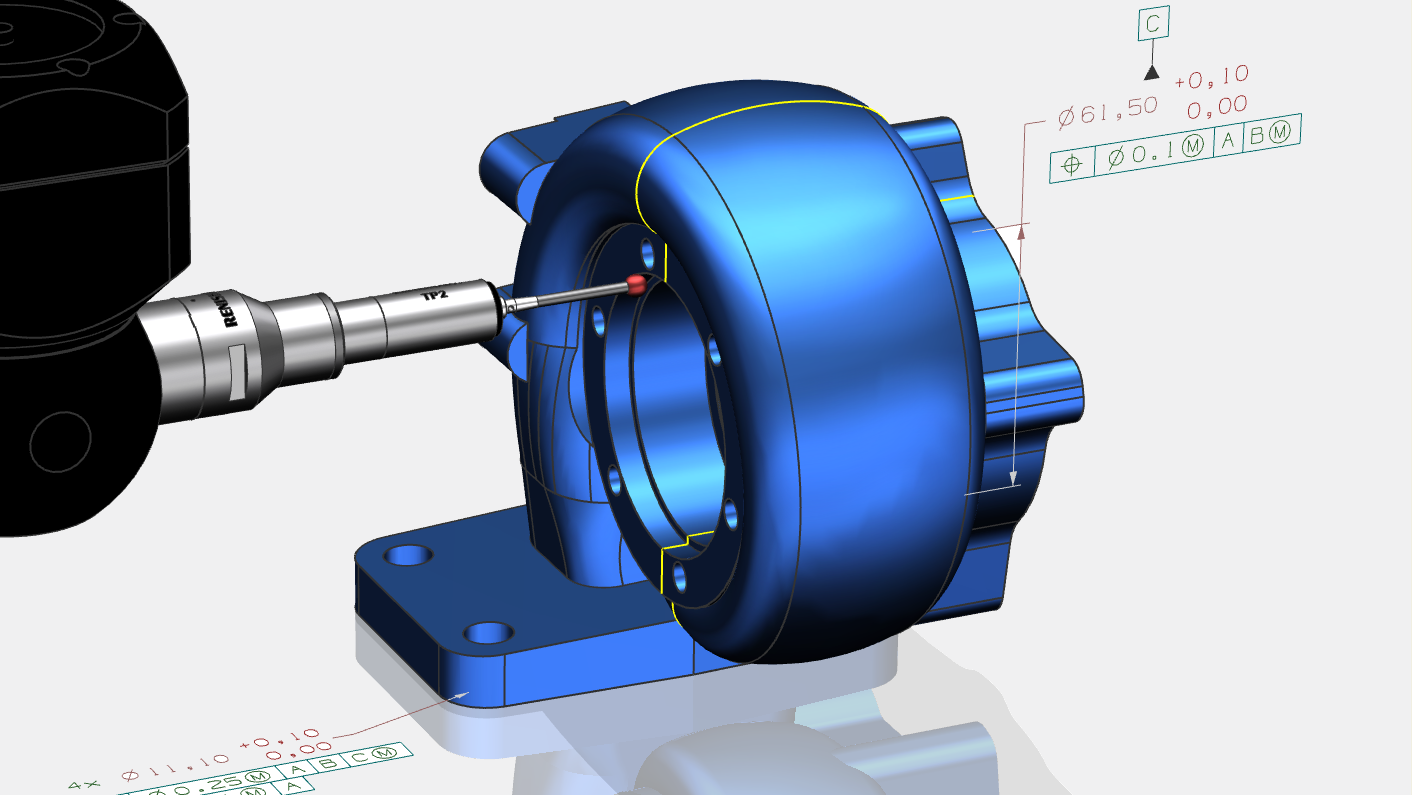

Inspection Data Analysis

NX™ software offers powerful 3D modeling and visualization features that allow you to map as-built, as-measured quality data directly on the as-designed geometry for visual analysis of the deviations from nominal.

Inspection Program Execution

NX™ CMM Inspection Programming software allows you to generate quality inspection programs, typically in the industry-standard dimensional measurement interface specification (DMIS) formats

In either case, the measurement results from the CMM can be sent back to the NX CMM Inspection Programming software for analysis and reporting.