CAM Software

Program any job using one software. NX CAM provides comprehensive and integrated NC programming capabilities in a single system. This enables the use of consistent 3D models, data and processes to seamlessly connect planning and shop floor operations with a digital thread.

You can streamline and automate NC programming, while reducing cycle time, using powerful, application-specific tools. From 2.5-axis machining and mold manufacturing, to simultaneous 5-axis milling and high-volume production, NX allows you to use one CAM software to make better parts faster.

Capabilities of CAM Software

- Prismatic Parts Machining

- Mold, Die & Electrode Machining

- Complex Parts Machining

- Postprocessing & Machining Simulation

Prismatic Parts Machining

Quickly create optimized NC programs for prismatic parts with minimum input. Automated capabilities in NX CAM, including volume-based milling and feature-based machining help you reduce programming time by up to 90 percent.

For higher volume production machining, NX helps you program multiple parts over multiple setups and machines.

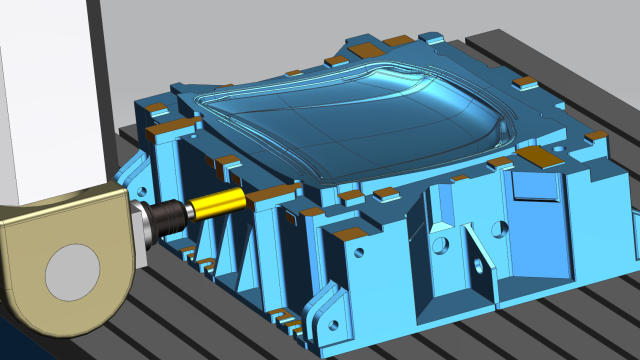

Mold, Die & Electrode Machining

High-speed machining, automated rest milling, and smooth finishing methods help you produce molds and dies with a near-mirror finish, while reducing lead time. Make better molds, dies, and electrodes using a single software system. NX CAM advanced capabilities for high-speed machining, automated rest milling, and smooth finishing methods help you produce high-quality tooling faster

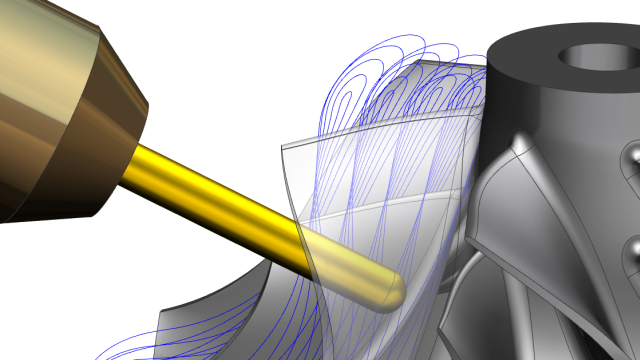

Complex Parts Machining

With 5-axis machining, you can produce complex parts with fewer operations and setups – reducing cost and delivery times. NX CAM’s 5-axis capabilities allow you to create precisely controlled tool paths to effectively machine complicated geometries.

The software’s application-specific capabilities can dramatically simplify programming of the most complex parts, such as impellers, blisks, and engine ports

Postprocessing & Machining Simulation

Generate NC programs for a wide range of CNC machine tools with NX’s integrated postprocessor. The machine-ready NC programs enable you to increase machine tool utilization and overall production efficiency. Leverage the digital twin of your machines and entire production lines to validate operations before you start the production. By using the integrated G-code-driven machine simulation in NX CAM you can optimize manufacturing processes and eliminate errors on the shop floor.