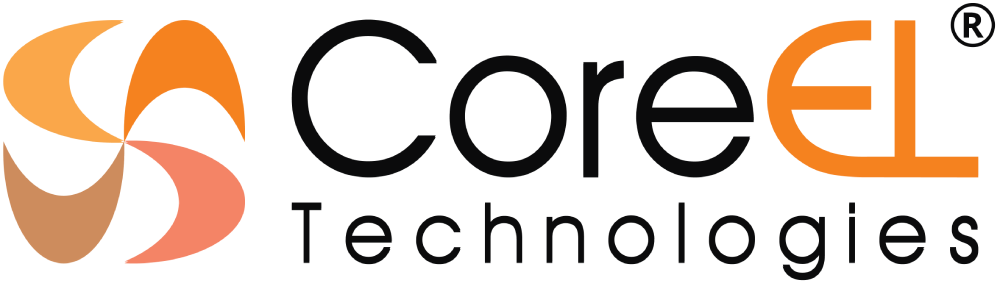

Ansys Sherlock offers a comprehensive solution for predicting the operating lifetimes of electronic components, which is crucial for maintenance planning and warranty cost calculations. It features embedded libraries with over one million parts, allowing for rapid conversion of electronic CAD files into computational fluid dynamics (CFD) and finite element analysis (FEA) models. These models include accurate geometries and material properties, translating stress information into validated time-to-failure predictions. Sherlock’s parts databases are linked to the Ansys Granta Materials Selector, and it supports various analyses such as shock, vibration, and thermal cycling. The integration with Ansys Workbench simplifies the generation of system-level reliability predictions.

| Capabilities |

| Reliability Analysis: Predicts failure modes due to thermal, mechanical, and electrical stresses. |

| Thermal Management: Simulates thermal cycling and stress to manage temperature variations. |

| Mechanical Stress Analysis: Assesses impact of mechanical stresses on electronic assemblies. |

| Automated Reporting: Provides detailed reliability reports and failure analysis. |

| Design Optimization: Enhances electronic system designs to improve reliability. |

Ansys Sherlock is the only reliability physics-based electronics design tool that provides fast and accurate life predictions for electronic hardware at the component, board and system levels in early stage design. Ansys Sherlock automated design analysis provides fast and accurate life predictions for electronic hardware at the component, board and system levels in early design stages. Sherlock bypasses the ‘test-fail-fix-repeat’ cycle by empowering designers to accurately model silicon–metal layers, semiconductor packaging, printed circuit boards (PCBs) and assemblies to predict failure risks due to thermal, mechanical and manufacturing stressors–all before prototype.

- Validated Time-To-Failure Predictions

- Ansys Icepak & Mechanical Integrated Workflow

- Rapid ECAD to FEA Translation

- Complete Product

Quick Specs

With embedded libraries containing over 500,000 parts, Sherlock rapidly converts electronic computer-aided design (ECAD) files into computational fluid dynamics (CFD) and finite element analysis (FEA) models. Each model contains accurate geometries, material properties and translates stress information into validated time-to-failure predictions.

- Drop Test Simulation

- Locked IP Model

- Default Package Geometries

- Thermal Analysis Prep

- Over 500,000 Parts Library

- Ansys Workbench Integration

- PCB and PCBA Materials

- Shock/Vibration/Thermal Cycling Analysis

- 1-D/3-D Solder Failure Predictions

- Trace & Via Capture

Key Features

Unlike any other tool on the market, Sherlock uses files created by your design team to build 3D models of electronic assemblies for trace modeling, post-processing of finite element analysis and reliability predictions. This early insight translates to almost immediate identification of areas of concern and gives you the ability to quickly adjust and retest designs.

- Builds and tests virtual products

- Modifies designs in near real-time

- Quickly runs mechanical simulations

- Evaluates and optimizes design choices

Pre-Processor for Ansys Mechanical & Ansys Icepak

Sherlock’s over 500,000 parts materials library enables the creation of accurate and complex FEA models. These models can be imported directly into Mechanical and Icepak for improved model fidelity and analysis.